GENERAL PRESENTATION

of the bi-rail overhead accumulation conveyor

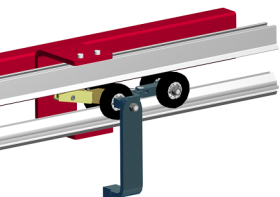

The Apollo twin-rail overhead conveyor is an automated transport and handling system for light loads. This conveyor transports parts between workstations and production islands within an industrial production area. Technimanut’s product transport process is unique in that it allows loads to accumulate. The parts to be transported are suspended from trolleys, load bars or spreaders, which are driven by the conveyor chain.

What is so special about accumulation?

In overhead handling, accumulation is a technology that makes each product independent. Accumulating loads on a conveyor enables parts to be stored and redistributed in different areas of an industry, all without taking up floor space! Accumulating products overhead can make each link in a production line independent.

Carrying light loads of up to 100 kg

Storage of your loads by Power & Free accumulation :

no contact between transported parts

Optimises the use of your space

by freeing up floor space

TECHNICAL DESCRIPTION

of the birail overhead accumulation conveyor

- Disengaging trolleys for workstations or storage areas

- 08B steel chain inside PVC guide

- Automatic or manual chain tensioner

- Connection between conveyors using rotary switches

- Standard radius of vertical track bend: 2000 mm

- Standard horizontal track bend radius: 115 mm – 240 mm

- The space between the parts being transported is given by the length of the trolleys

- Integration of touch screens depending on the type of associated control system

- Motorised system

- Aluminium rail for a compact conveyor system

- Used to create a stop station

- Enables you to create storage areas

- Allows you to create turnouts

- Integration of a loader/unloader

- Can be identified by RFID or barcode

- Integrating weighing stations

- Integrating transfer stations

- Possibility of adapting travel speed

- Possibility of integrating manual or gravity load shifting

Automatic seal dryer

The Apollo bi-rail overhead conveyor can be installed in all sectors of activity where there is a need to accumulate a load and deliver it when required.

This conveyor is frequently installed in seal manufacturers.