Solutions for handling, storing and transferring parts

BY ACCUMULATION IN THE AUTOMOTIVE INDUSTRY

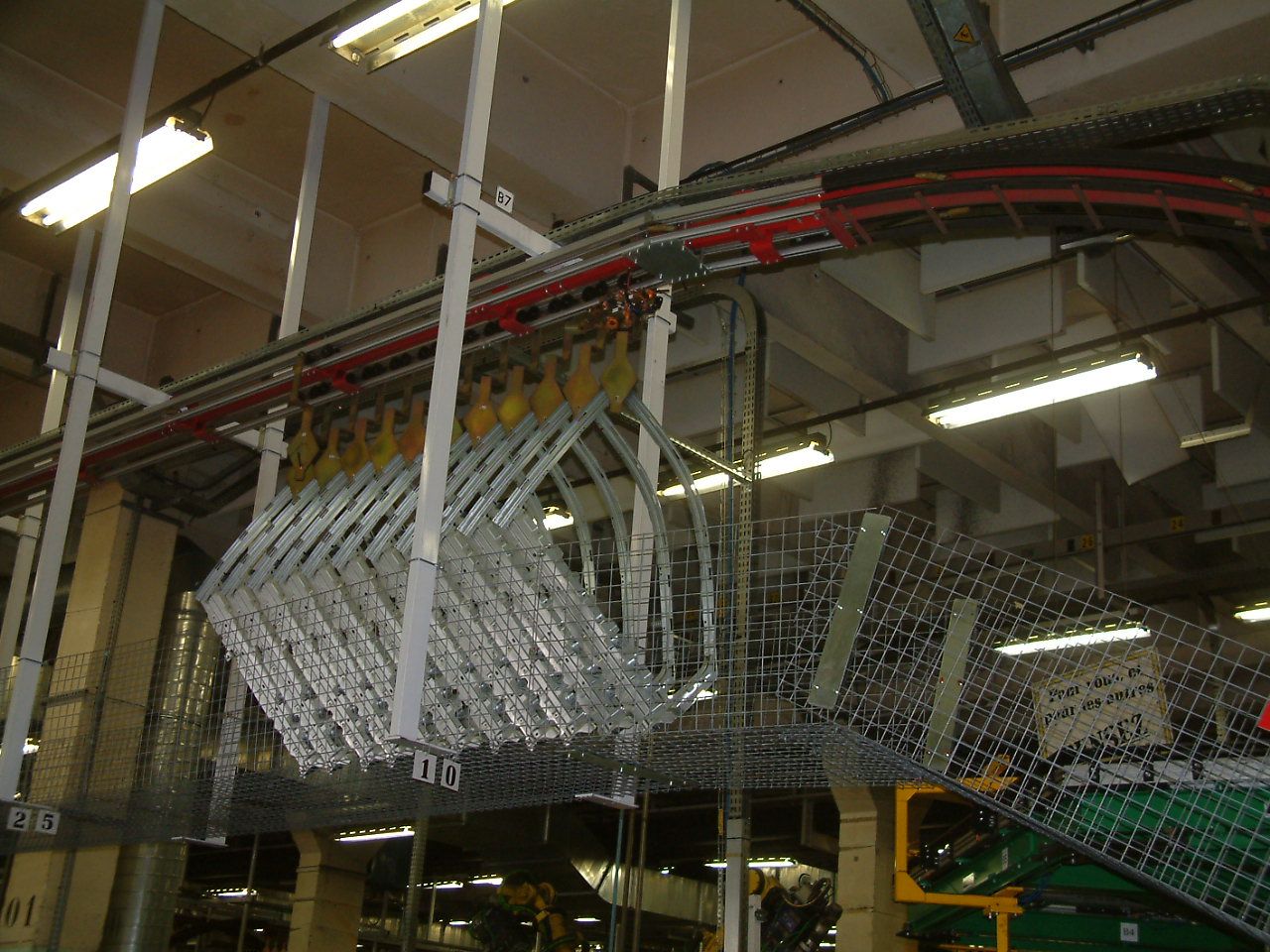

Our overhead conveyor system offers a solution for hanging, storing, moving and transferring parts on automotive production lines. The Technimanut twin-rail overhead chain conveyor makes it easy to handle your parts when:

- welding

- assembly

- control

- etc.

As well as providing handling assistance on production lines, our conveyors also provide solutions in:

- warehouse management in industry

- improving the ergonomics of operators’ workstations

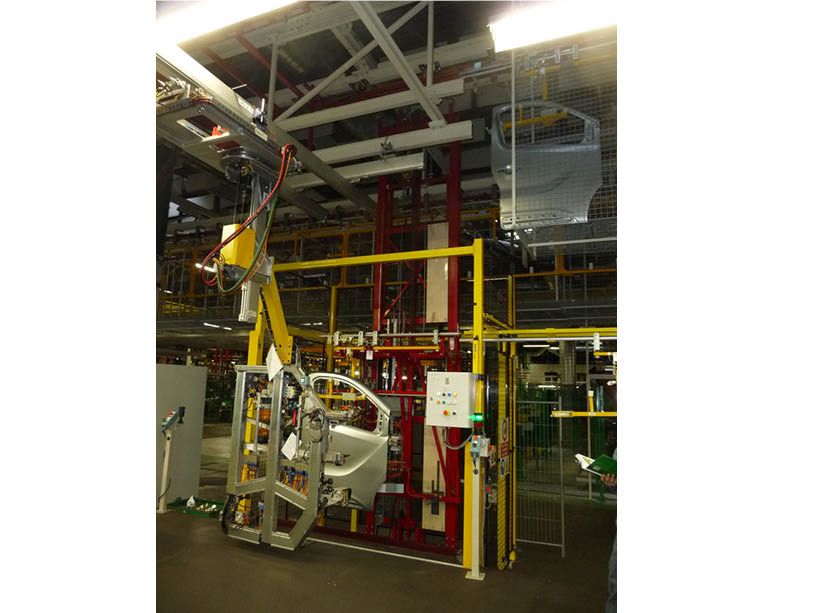

Our system for transferring and transporting parts on a bi-rail chain in the automotive industry can therefore be adapted to a variety of products such as:

- vehicle tailgates

- vehicle doors

- engine mounts

- of motors

- vehicle bumpers

- automotive seals

- electrical components

- steering wheels

- windows

- exhaust lines

- etc.

Whether you produce small or large parts, the Technimanut twin-rail conveyor provides a solution for storing and transporting light parts in series to facilitate and optimise productivity in the automotive industry.

Our bi-rail air transport system allows loads to be accumulated using the power & free system. This technology makes it possible to:

- deliver products according to the needs of production operators

- put certain parts on hold before being processed by another operator

- link workstations or robotic islands, while making them independent. The power & free bi-rail conveyor offers certain operators the possibility of working at a pace that does not depend on the imposed production rate.

What’s more, as our load transport system is motorised, it ensures that your products move at a constant speed and integrates perfectly into an automated production process/line. Your parts are then transported autonomously, making your production lines run more smoothly and more efficiently. Our overhead conveyor is not just a closed automatic circuit, it’s a system of rails that creates different storage areas.

Thanks to our method of transporting loads by accumulation, we offer safe and ergonomic working conditions that prevent musculoskeletal disorders and free up floor space.

As a supplier of turnkey installations, Technimanut provides you with the entire management system for your overhead accumulation conveyor for the automotive industry.

ADVANTAGES

- requires little maintenance

- low energy

- modular and adaptable to all types of buildings

- silent

- frees up floor space

- improves loading and unloading

- simplifies load transfers with other machines as the overhead conveyor can be stopped

- serves a large aerial area in your industry by integrating switches

- possibility of creating dynamic storage (storing and accumulating different references)

Options for accumulator handling solutions

IN THE AUTOMOTIVE INDUSTRY

Our accumulating overhead handling systems can be fitted with options and can offer you the possibility of:

• load and unload your products using robots

• load heavy parts with a loading table that accompanies your part

• add switches to stock more references and serve a larger aerial surface area

Watch a video of our overhead accumulation conveyor

IN AUTOMOTIVE INDUSTRY

Do you need a storage and transport system for your automotive parts production ?

Other sectors in which

TECHNIMANUT OPERATES